Heat and cold protection with composite elements of Stadur-Süd

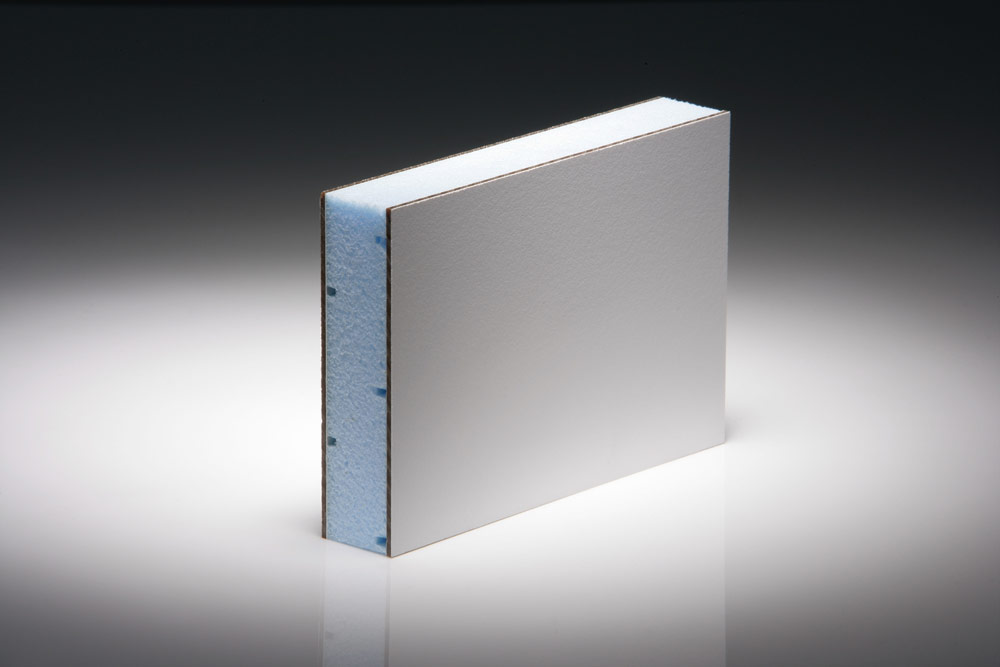

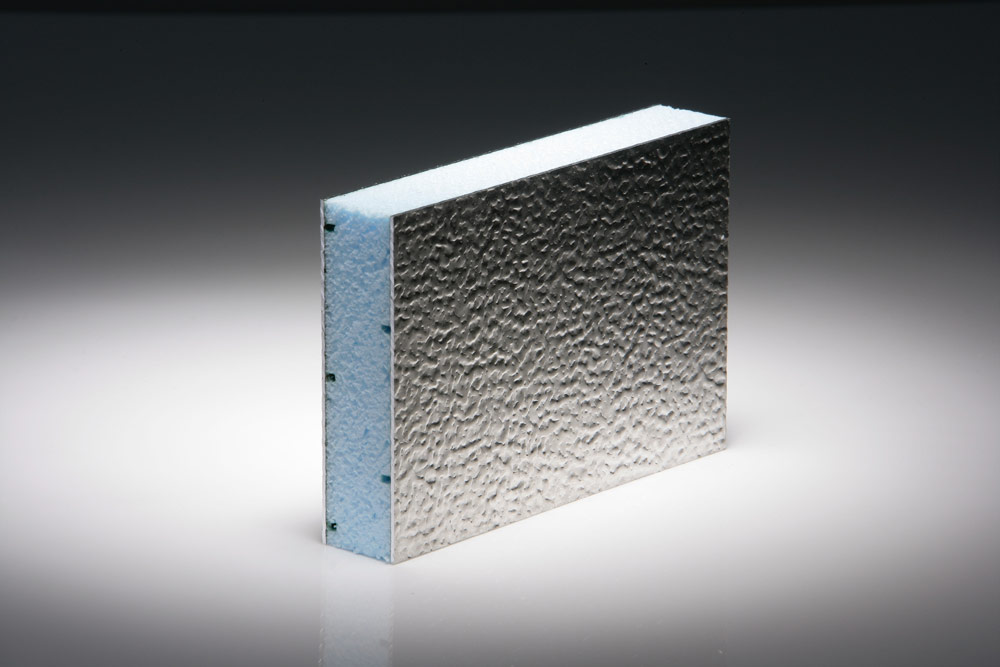

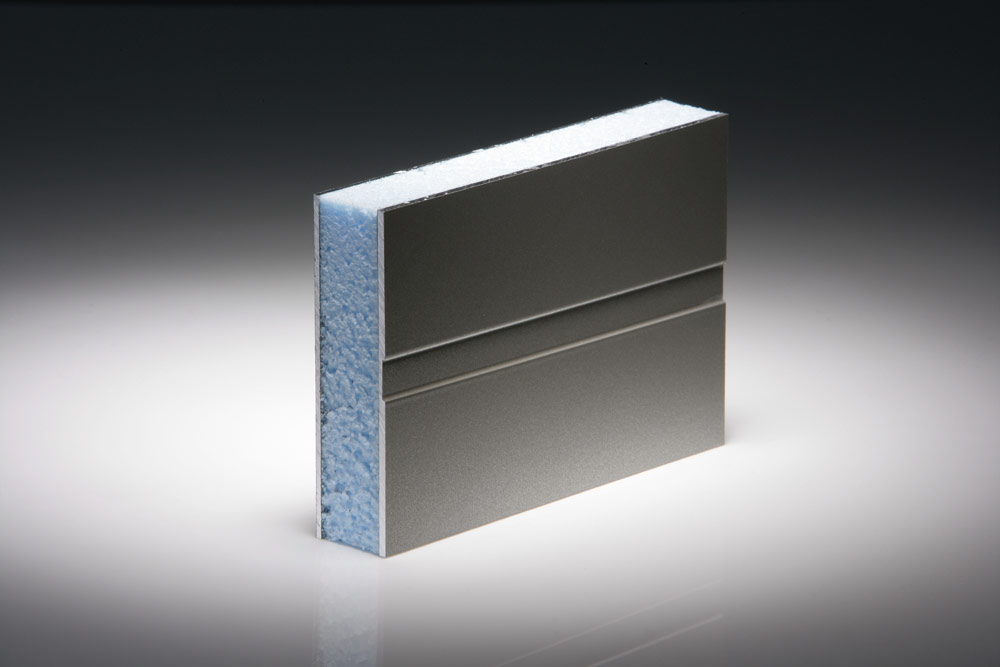

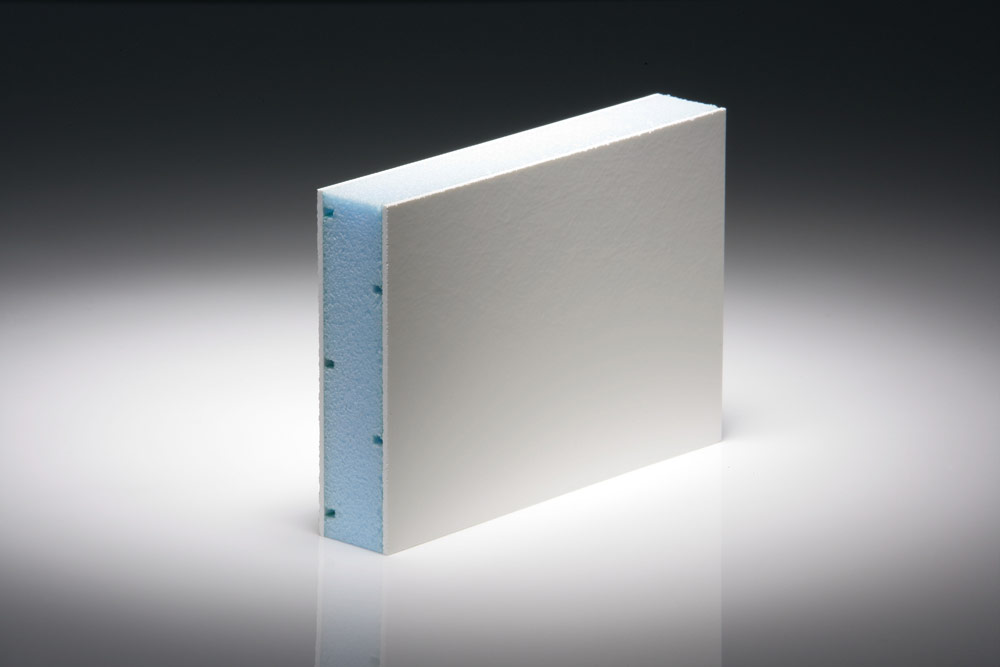

Thermal insulation, sound insulation, burglary protection. These are the threebasic requirements of composite elements. In order to fulfil these it is necessary to provide the customer with comprehensive and professional advice on the ideal coating materials and core layer construction for the composite elements. In addition, we can cut theinsulation materials to any shape. Two-dimensional shapes are made for a wide variety of applications. We are very proud to be one of only a few companies that can also offer three-dimensional parts.

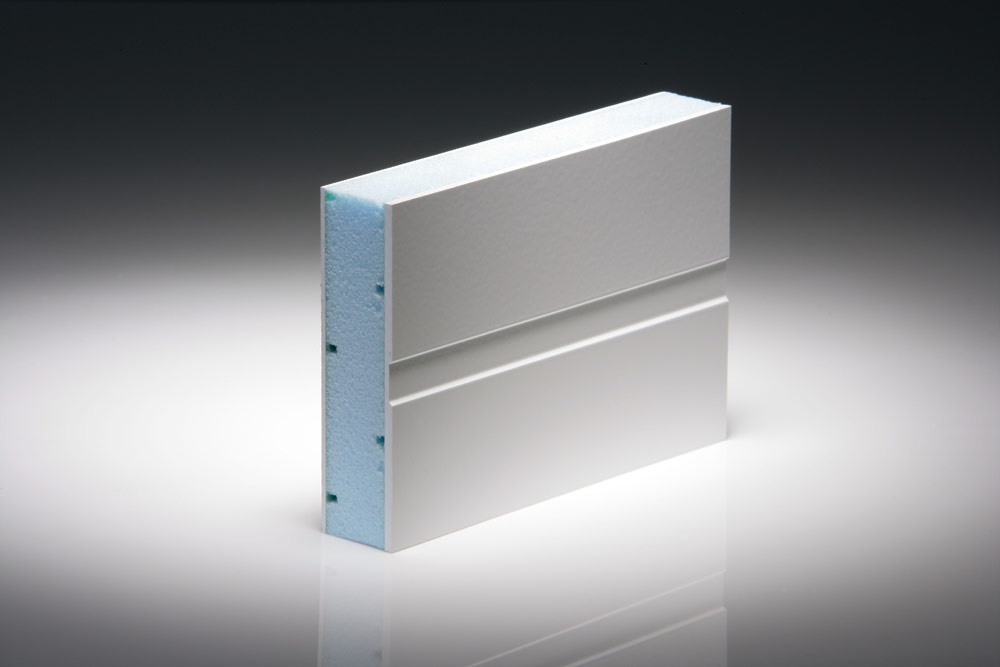

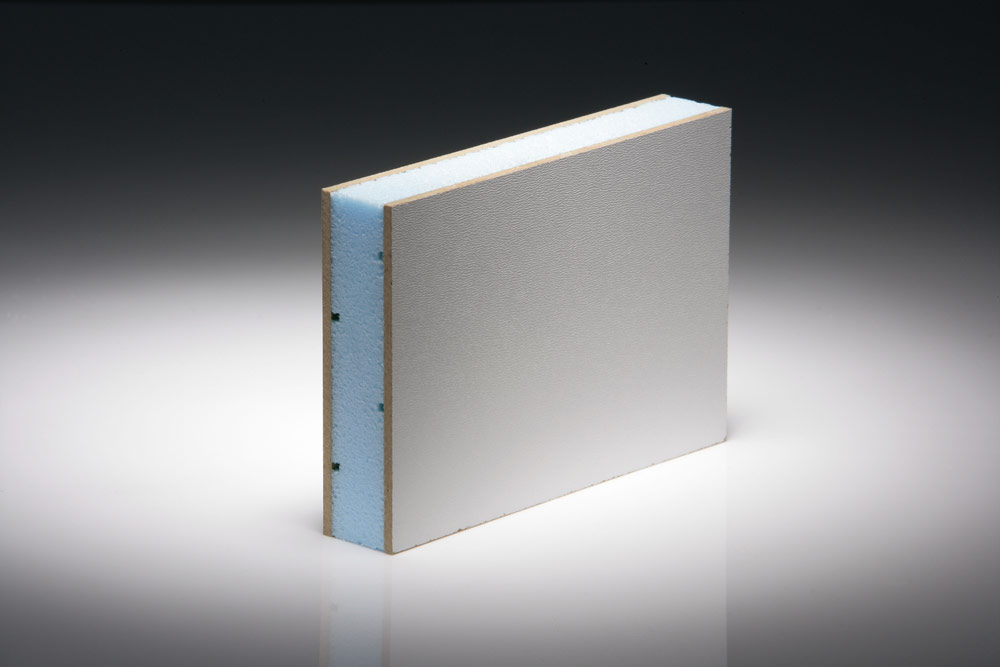

The most important prerequisite for a good composite element is the core layer material. That is why we use the extruded polystyrene foam Styrofoam* FB for Stadur composite panels. Grooves are created in the Styrofoam core using a special procedure. The grooves facilitate the bonding process as they promote air desorption and improve the mechanical bondability of the adhesive with the foam surface. Because of its closed-cell structure, Styrofoam* offers excellent properties as a quality core layer for FB elements:

|

|

*trademark – The Dow Chemical Company

**the propellants used in the Styrofoam products comply with German federal regulations, specifically the CFC halon regulation (FCKW-Halon-Verordnung) of 6 May 1991